Description

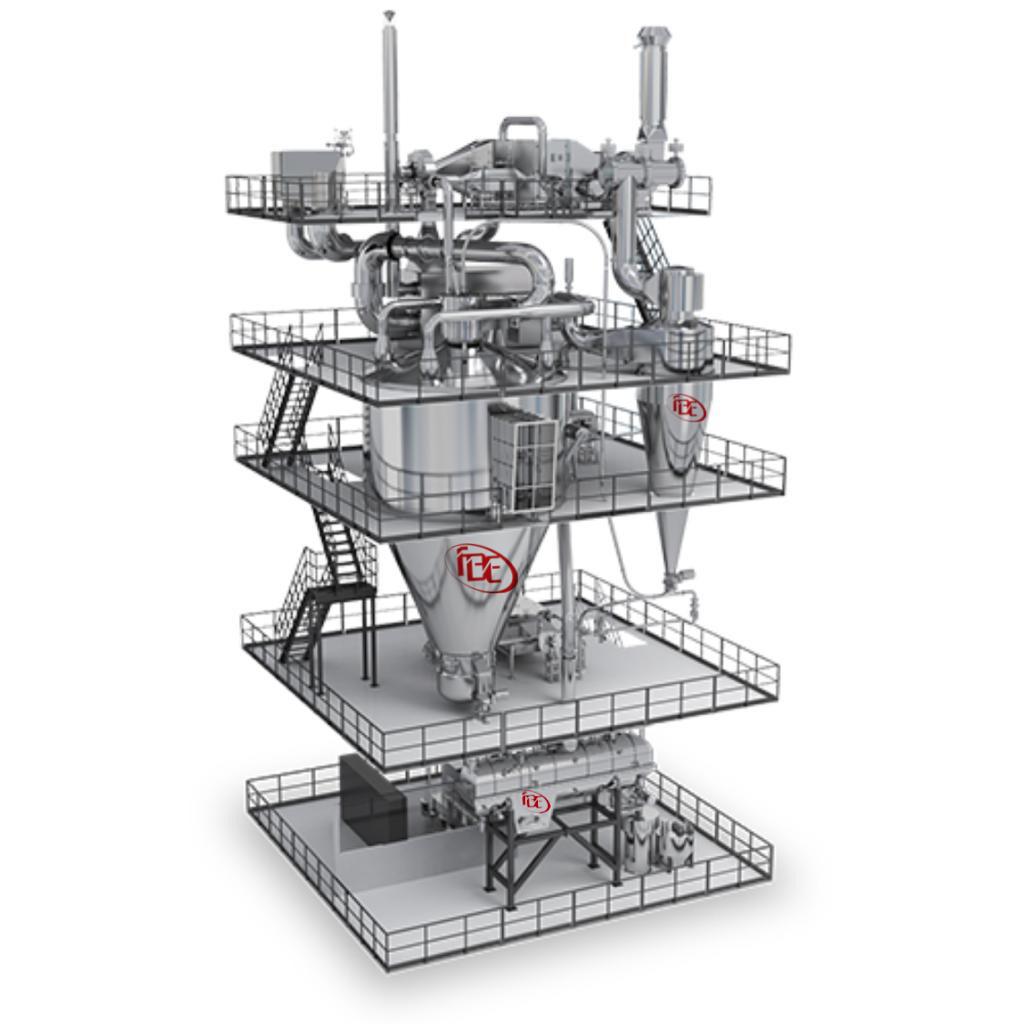

Spray drying is transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. It is a continuous particle-processing drying operation. The feed can be a solution, suspension, dispersion, emulsion or slip. The dried product can be in the form of powders, granules, or agglomerates.

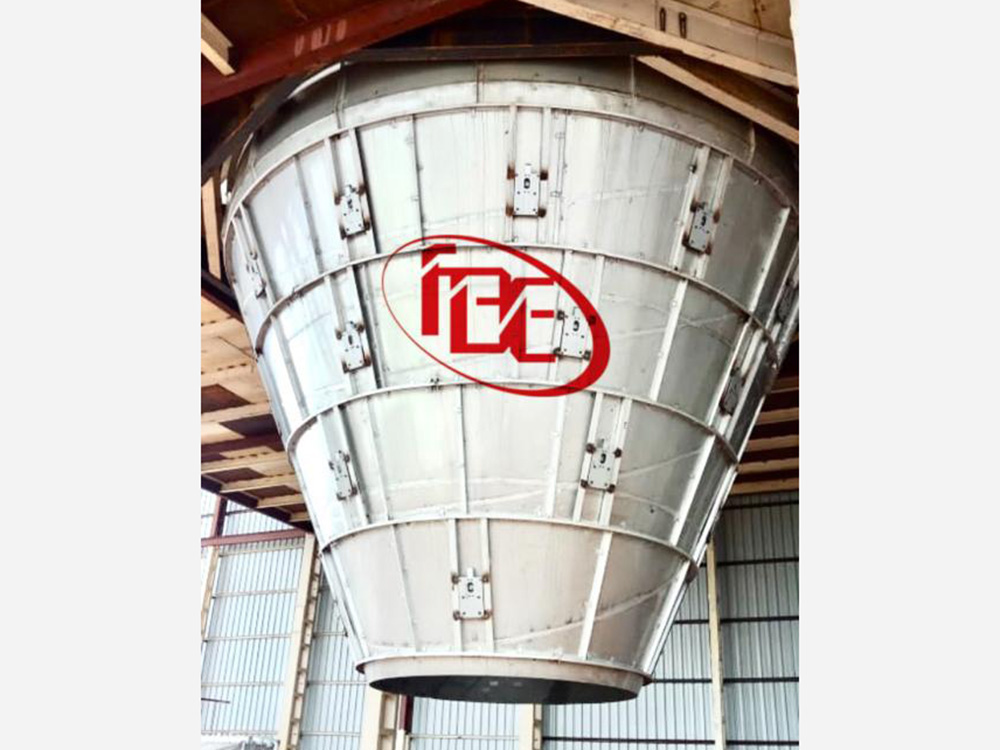

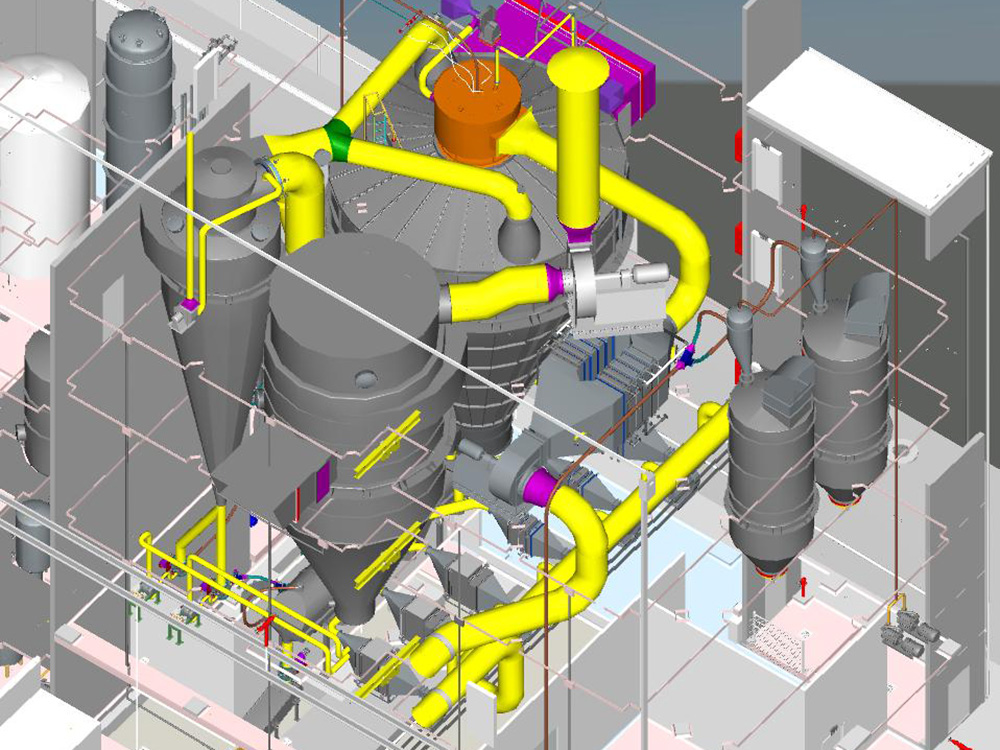

Feed is finely atomized and is introduced in the drying chamber along with hot air. The mixture of atomized feed and hot air moves towards the air exhaust of drying chamber. The time taken by this mixture to travel upto air exhaust is called as residence time of drying. During this residence time, the feed droplets loose its moisture to the hot air and are converted into dry powder particles. The dry powder falling on to the conical portion of drying chamber slides down to bottom of drying chamber with the assistance of vibrators/knockers and is collected in collection bag/bottle through the rotary valve located at the bottom of drying chamber.

The air leaving the drying chamber entrains some of the dry powder which is recovered in the cyclone separator and collected through rotary airlock. The air leaving the cyclone separator still has traces of dry powder, which is further recovered by scrubbing in wet scrubber or passing it through bag filter. Air from cyclone or bag house is sucked by induced draft fan

Application:

- Milk Powder Plant (SMP/ WMP/ Dairy Whitener)

- Herbal Extracts

- Whey powder

- Fruit juice powder

- Instant coffee powder

- Egg powder

- Maltodextrin powder

FBE manufacture Spray dryer with following types of drying chamber

- Tall form dryer

- Multi stage dryer (Ceiling exhaust)

- Compact Multistage dryer (Bottom exhaust)

Salient Features of FBE designed Spray Dryer

- Drying & particle formation in one process.

- Wide range of particle size and distribution can be obtained.

- Reduced running cost

- Fully automatic operation which requires very little human intervention.

- Continuous production machine without human touch.

- Provision of cooling cum conveying system.

- Bottom cone angle of drying chamber is optimized to induce problem free powder slide across the cone.

- Unique Air Disperser designed with uniform distribution of air in dryer chamber and uniform air velocity profile around atomization space resulting in minimised powder sticking and reduced downtime.

- Air exhaust from high efficient cyclone & filter bag house

- Quick opening manholes/cleaning windows.

Reviews

There are no reviews yet.