Description

| Type | Milk Processing Plant |

| Automatic Grade | Automatic |

| Computerized | No |

| Color | Silver |

| Sr. No | Powder Specification for Agglomerated Powder | SMP | WMP (Lecithinated) |

| 1 | Fat | <1 % | >22 % |

| 2 | SNF | >96 % | 75.2% |

| 3 | Moisture by mass | <3.5 % | <2.8 % |

| 4 | Sugar | NIL | NIL |

| 5 | Insolubility Index | 0.2 ml | 0.3 ml |

| 6 | Bulk Density | 0.4-0.5 | 0.4-0.5 |

| 7 | Scorched Particle | Disc A | Disc A |

| 8 | Wettability at 49ºC (after 72 hours of storage) | <30 sec <30 sec | <30 sec <30 sec |

| 9 | Dispersibility (min.) % | 85% | 85% |

| 10 | Free fat | NA | <1% |

Salient features of FBE Make Evaporators

- Adjustable and controllable direct contact heat treatment units.

- Shortest possible residence time.

- Special design to prevent bacteriological growth including thermophiles.

- Special design of liquid distribution systems to ensure correct tube coverage.

- Extended tube length.

- Efficient design of separators.

- Low energy consumption (Steam, Power, cooling water).

- Easy operation.

- No scale formation in tubes.

Salient features of FBE Make Dryers

- Good plant performance due to the absence of any air flow obstruction inside the chamber

- Good agglomeration potential.

- Instant quality of powder is formed.

- Higher plant capacity for a given size.

- Low energy consumption.

- Alternate arrangements of Rotary atomization or nozzles in the same dryer

- Used for the whole range of dairy products as the SMP, WMP, DW etc.

- Single stage spray dryer and Spray dryer with IBD and VFD shall be used alternately in the same plant

- Fines-return to atomization device or VF

- Pneumatic cooling and conveying system in stead of VF

- Pneumatic cooling and conveying system in stead of VF

- Air exhaust through centre duct in the chamber.

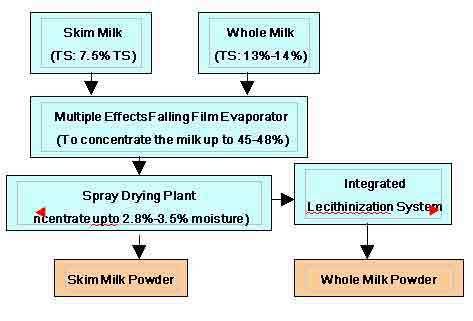

Advantage of Lecithinization system

- Lecithinization system is integrated with Spray dryer to manufacture Whole milk powder.

- The lecithinization refers to the coating of powder by a wetting agent consist of lecithin dissolved in butter oil. The wetting agent is sprayed to powder under fluidization in VFD, so that good quality of WMP s produced with it.

Reviews

There are no reviews yet.