Description

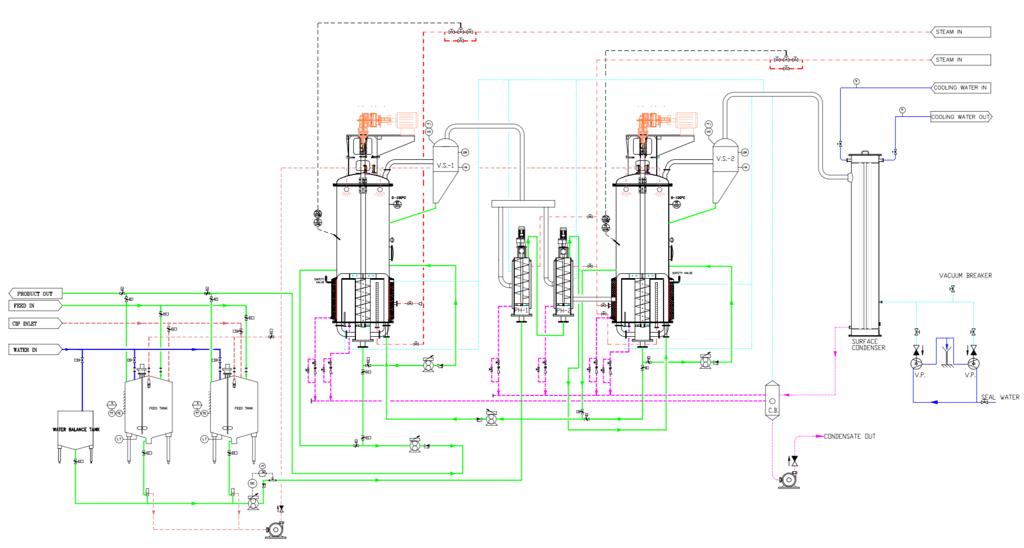

A Process & MVR Brief Description

Types of constriction of MVR

In evaporation plants, the three types are used:

- Centrifugal fans

- Centrifugal (turbo) compressors

- Rotary (roots) blowers

Centrifugal Fans

Centrifugal fans are continuous-flow machines consisting of a spiral-type housing which accommodates a rotating impeller with radially ending blades or with backward-bent blades.

Centrifugal (turbo) compressor

Centrifugal compressors are also continuous-flow machines in radial construction with an energy transfer comparable to that of a centrifugal fan. Centrifugal compressors also consist of spiral-type housing with axial suction nozzle, accommodating a rotating, usually semi-open impeller.

Rotary Blower

In a Rotary Blower or, Roots Blower, two, two-or three-blade rotary pistons rotate in opposite directions. In a simple design, a rotary piston has a symmetrical, octagonal shape. Together with the circumferential housing, it builds a so-called conveying chamber in which the vapour is conveyed from the suction side to the pressure side of the machine.

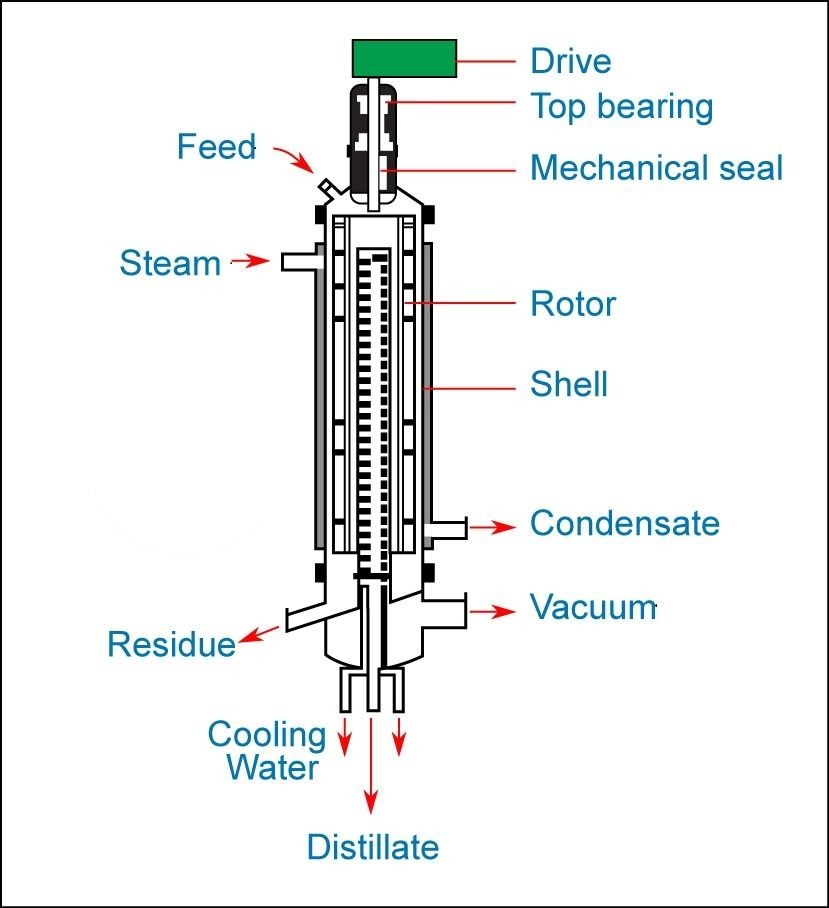

B Principles of Function and Design Features

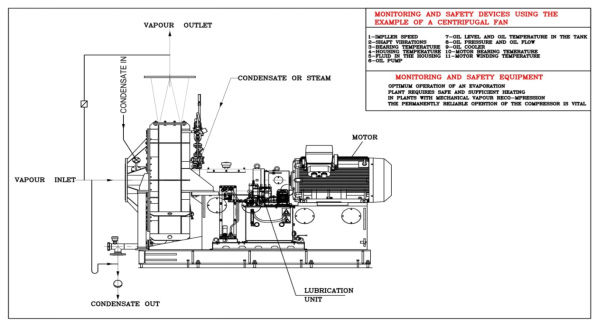

Monitoring and Safety equipment

Optimum operation of an evaporation plant requires safe and sufficient heating. In plants with mechanical vapour recompression, the permanently reliable operation of the compressor is vital.

Monitoring and Safety Devices using the example of a Centrifugal Fan:

- Impeller speed

- Shaft vibrations

- Bearing temperature

- Housing temperature

- Fluid in the housing

- Oil pump

- Oil level and oil temperature in the tank

- Oil pressure and oil flow

- Oil cooler

- Motor bearing temperature

- Motor winding temperature

Compressor drives

Several types of motors are suitable as drive of a vapour recompressor. The selection of the drive depends on its efficiency and availability of the drive energy in each individual case.

Three-phase current asynchronous motor

The three-phase current asynchronous motor runs according to the number of its pole pairs at speeds of 3,000, 1,500, 1,000 or 750 rpm – in synchronism with the mains frequency – or – if a frequency converter is used – at infinitely variable speed.

The most important regulation variants for centrifugal fans and turbo-compressors are:

- Speed control

- Pre-rotation control

- Suction pressure control

- Bypass control

Retrofitting

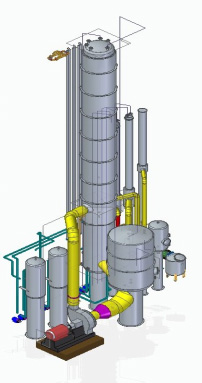

Existing Multi Stage Evaporator can be modified for heating by means of MVR. After the retrofitting measures, the existing effects are heated in parallel. For this purpose, the existing vapor ducts are dismantled, one or more mechanical recompressor are installed and new vapor ducts are installed. In this way, the energy flow in the plant is changed such that the major part of the evaporated vapor is now used to heat all effects. Only very small quantities of live steam and cooling water are required.

Investment

The costs for such a retrofitting will amortize within a short period of time.